As part of a substantial recapitalisation programme, Sheffield Forgemasters has signed a contract for furnaces with Dewsbury-based Northern Combustion Systems (NCS).

NCS will supply two, bespoke, Top-Hat Furnaces for the Sheffield company’s new Forging Line under the multi-million GBP contract, which will enable the company to manufacture critical components for the UK/SSN-AUKUS submarine programmes and other key defence programmes.

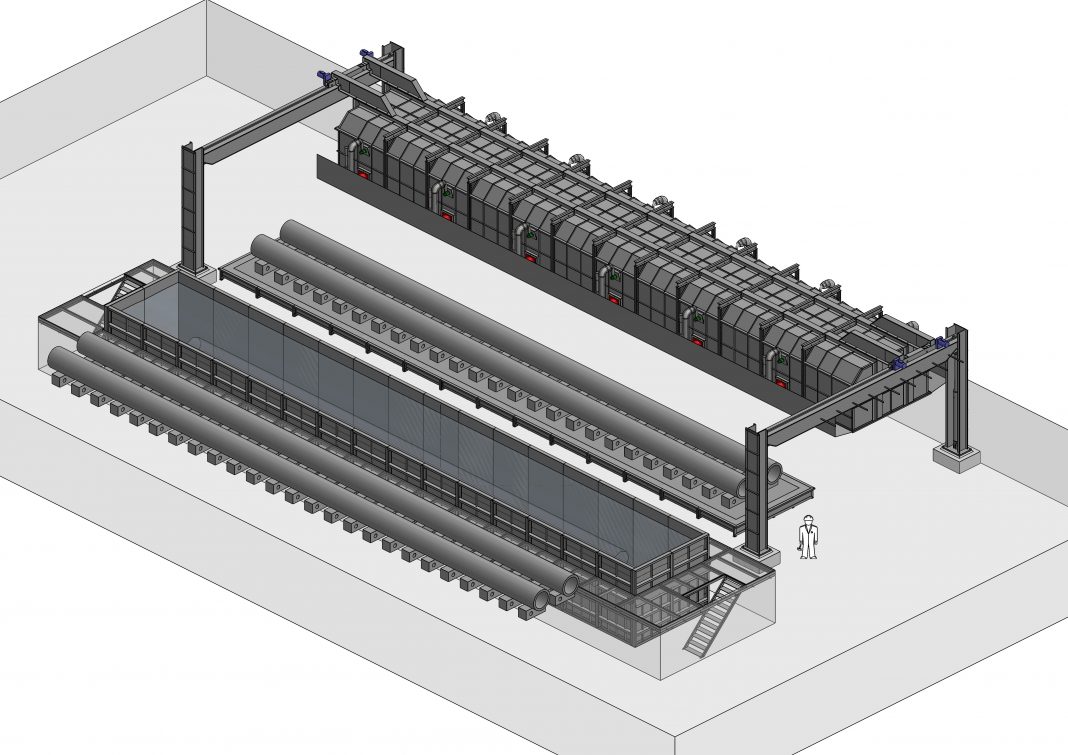

Following a robust tender process, which considered cost, delivery and capabilities, NCS will deliver furnaces with a distinctive lift off cover appearance, with both furnaces adopting a hydraulically operated lift and a traverse cover for the heat treatment of long, forged components.

Craig Fisher, Programmes Director at Sheffield Forgemasters, said: “Northern Combustion Systems has 40 years of experience in industrial furnaces manufacture and are providing Sheffield Forgemasters with two new high-efficient recuperative and modulating Top Hat furnaces.

“The furnaces will support our forging programme and the largest of the two includes an integral quench tank and is designed for longer forgings, while the smaller furnace will support ingot and bar heat treatments.”

Installation of the furnaces is scheduled for October 2025 and April 2027 as part of an investment programme to create new, unmatched facilities for the supply of defence-specific forgings and castings, and they will operate alongside seven larger furnaces.

Top Hat Furnaces feature a fixed hearth, with a removable cover, which contains the gas burners and refractory material.

The new Sheffield Forgemasters furnaces measure 11m long x 10m wide x 6m tall for the smaller of the two, and 30m long x 11m wide x 6m tall for the largest.