Doncaster-based Agemaspark has used 3D metal printing solution to help an international drinks company produce the bottle top of the future.

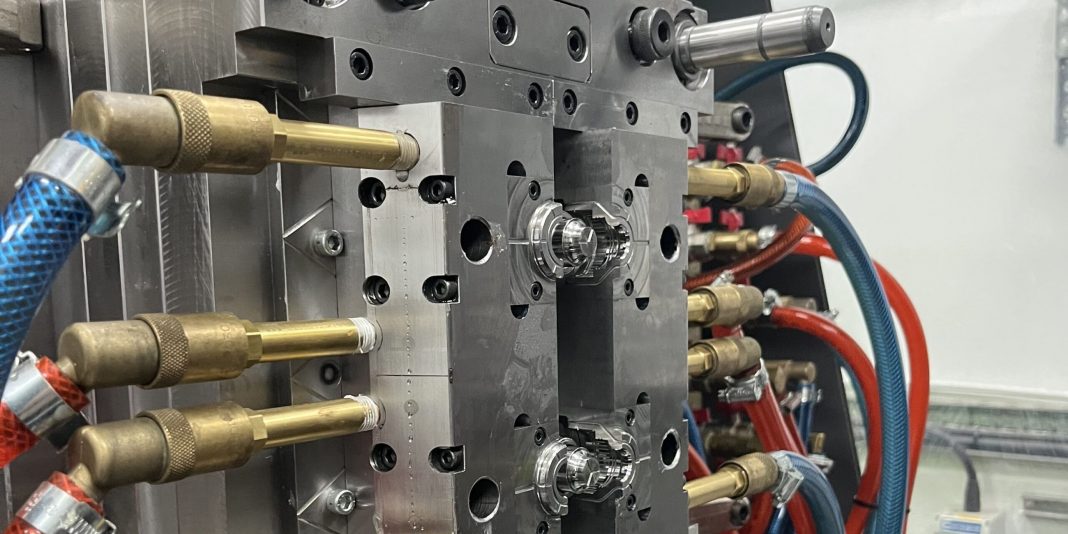

The firm has made mould tools for long-term customer Silgan Closures, which sells its closures in more than 50 countries across the globe. Their closures are used on liquid cartons and plastic sports drinks bottles, and need to be suitable for hot or cold drinks, be tamper-proof and resealable.

Paul Stockhill, MD of Agemaspark, said: “We have worked with Silgan Closures for more than 18 years on conventional moulding tooling for their plastic injection moulding components.

“Following an EU directive to change to tethered caps for drinks cartons we discussed making new mould tools with a view to improving the manufacturing process.

“We ran a number of trials of the moulds and have now delivered a product that enables these drinks caps to be manufactured in a more environmentally friendly way.”

Paul added: “We are extremely proud to have created the mould tool design concepts and tooling designs for Silgan Closures. It is fantastic to be working with them in partnership on their wide range of caps and closures.

“We are continuing to test moulds and designs and are now working on two new prototype tools for the company converting existing conventional tools to conformal cooling tools.

“It is great to see companies investing in improving the environmental impact of manufacturing and being innovative in their approach to delivering their product.

“Our techniques can be used to help industries from oil and gas to aerospace and from medical and clinical to tooling. We are looking forward to using this application to help more sectors improve their environmental foot print.”