The seventh annual cooling seminar run by Rotherham’s Nuclear Advanced Manufacturing Research Centre will explore the state of the art in advanced coolant techniques for the most demanding machining applications.

The one-day forum on September 21st brings together industrial users with researchers to discuss the opportunities and challenges of advanced cooling methods, and share the latest knowledge and innovation.

There will be speakers from leading engineering companies and research institutions to the AMRC Knowledge Transfer Centre to discuss their work across a host of industries and applications.

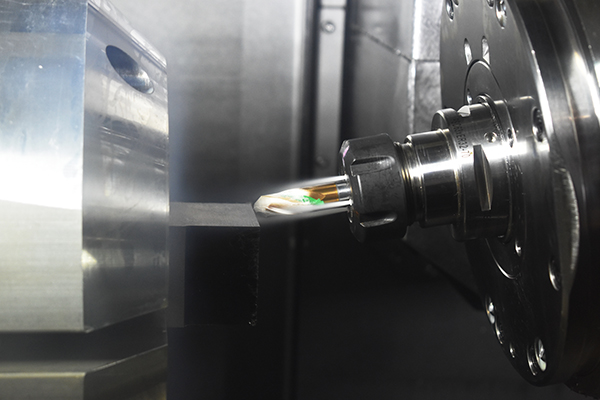

The Nuclear AMRC has led research into supercritical CO2 cooling over the past eight years, with a focus on combining CO2 with minimum quantity lubricant (MQL) techniques for optimum performance in the most challenging machining tasks. Recent projects include work with difficult-to-machine refractory metals such as tungsten for applications in the fusion power sector.

These advanced cooling techniques can improve component surface integrity, cleanliness, reduce the cost of the components, reduce waste and cut the environmental impact of machining. But in applications where quality and performance are critical, dedicated R&D is needed to optimise CO2 and MQL delivery parameters and cutting conditions.

To register, go to advancedcooling23.eventbrite.co.uk