Sheffield Forgemasters will make a trial forging to help in the the development of a pioneering green technology demonstration plant for fusion power – hailed as the holy grail of green energy generation.

The critical ring component, being made for Canada’s General Fusion, will confirm specifications for the next phase of the programme, to create a thick-walled fusion vessel designed to withstand the extreme high temperatures and compressive forces needed to create fusion energy.

The trial ring’s specifications match the 11 rings planned for the fusion demonstration machine. It will allow the engineering team to validate performance of the high-strength steel alloy, finalise the vessel design and confirm the manufacturing process for the fusion reactor.

David Bond, CEO at Sheffield Forgemasters, said: “Fusion is the holy grail of green energy sources and uses the same processes which power our sun, with the potential of virtually unlimited supplies of low-carbon energy.

“At Sheffield Forgemasters, we pride ourselves on our innovation, and have extensive knowledge and experience in establishing practical manufacturing solutions for disruptive technologies. We are thrilled to be a part of this project and actively working to bring fusion energy to the world.”

The fusion demonstration machine will create fusion conditions, including an internal temperature of 100 million degrees Celsius in a power-plant-relevant environment. Its results will provide the information needed to design and build a commercial pilot plant which could generate electricity at an affordable price.

Greg Twinney, Chief Executive Officer at General Fusion, said: “Sheffield Forgemasters brings to this project over 200 years of expertise creating complex steel components. Teaming up with world-leading specialists allows us to focus on our commercialisation plan and stay on pace to generate zero-carbon electricity by the early 2030s.”

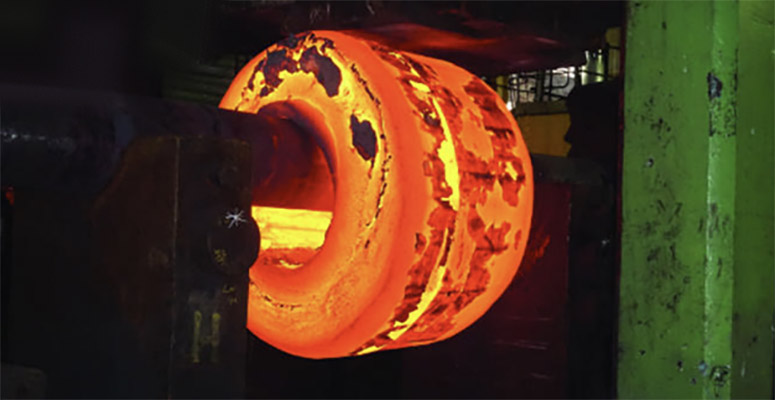

To create the trial ring, a large steel ingot has been forged in the UK’s largest open-die press, forming the steel into a donut shape with a diameter of just over three metres. The ingot will subsequently be rolled and expanded into a larger, thinner ring, spanning 7.6 metres in diameter.

56 holes will be drilled into the 42-tonne ring, replicating holes that will transmit high-pressure gas from the compression drivers to a spinning interior rotor in the fusion demonstration machine. The pressure change will push smaller pistons to collapse General Fusion’s proprietary liquid metal liner around hydrogen plasma and create fusion.